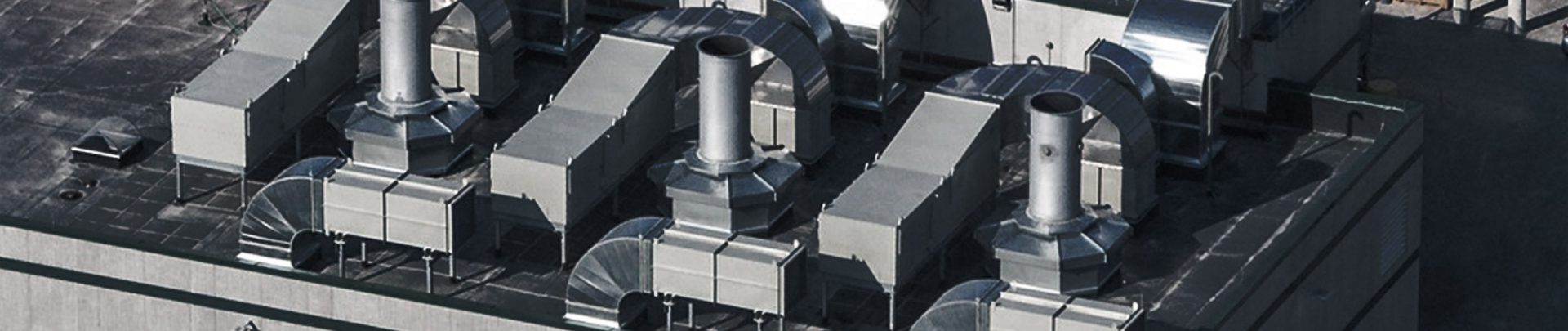

Ameren – Renewable Energy Center

Specialty contractor for a fast paced project to take something nobody wants, decomposing trash, and turning it into something everyone needs, reliable, environmentally-responsible electricity by building a new energy recovery plant and office. Ameren expected Haberberger and its subcontractors to maintain the project schedule which included hundreds of tasks and milestones. Ameren Missouri has invested millions of dollars in state-of-the-art low emission turbine technology (Mercury 50 gas turbines) to efficiently generate approximately 15 megawatts (MW) of renewable electricity by burning a landfill gas-methane – that was previously wasted. Ameren wanted to assemble a winning team that can overcome many of the project barriers to deliver a first class landfill gas to energy project that ultimately created jobs, demonstrated landfill gas (LFG) as a reliable renewable energy that benefited the community.

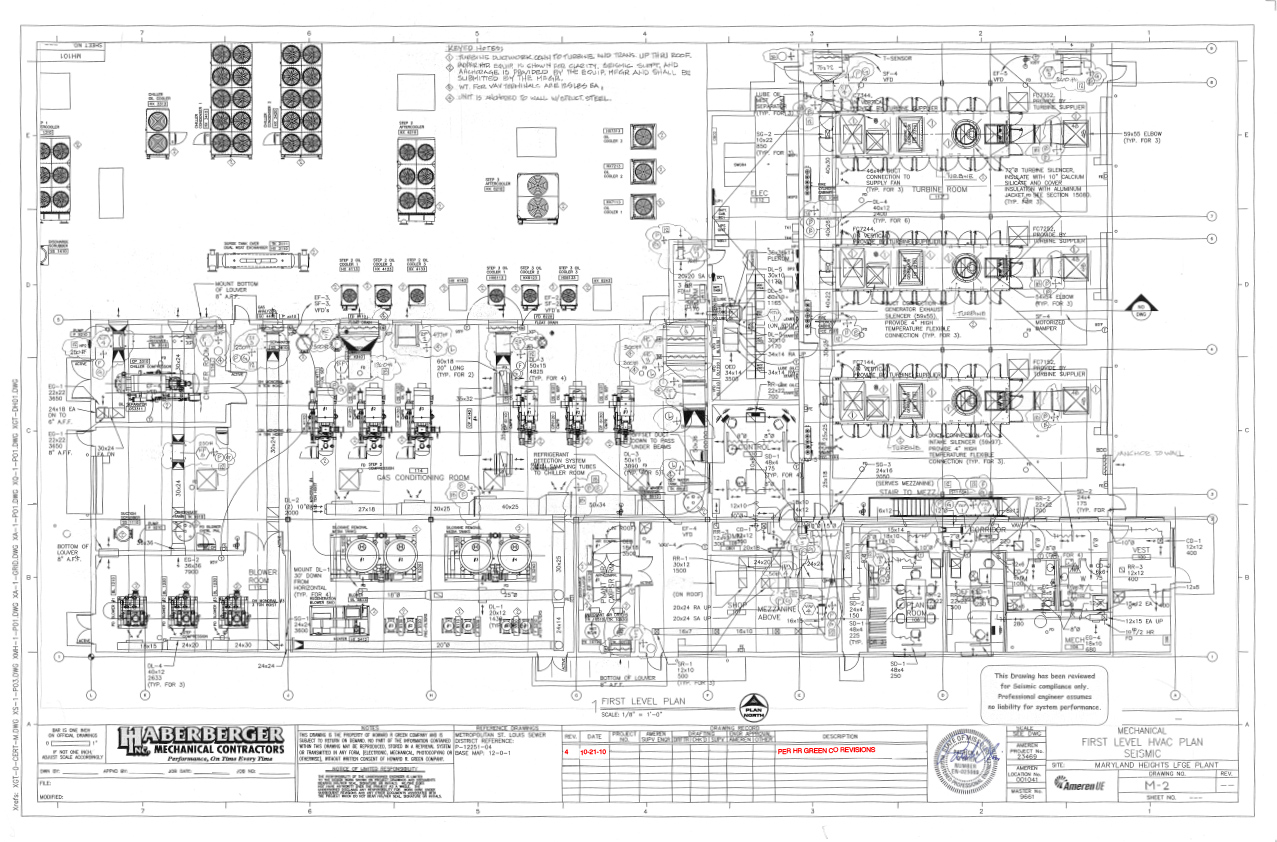

Project Sketches and Blueprints

Project Scope

Installed three positive displacement blowers, sulfa treat system, four scrubbing tanks, five screw compressor skids, chiller, two siloxane removal skids, regen flare, three Solar Mercury 50 turbines, exhaust fans, welded ductwork, HVAC system, and an air compressor. Setting of the equipment was challenging due to the fact that we only had fractions of an inch in some instances to fit the equipment through the openings in the buildings. Haberberger installed over 10,000 feet of pipe from ½” to 18” to make the system above a reliable and working system.

Project Outcome

One of the most challenging aspects of the project was the management of shipped loose equipment. Between parts shipped by the compression company, those provided by the controls contractor, the Regen flare vendor, electrical equipment vendors and the turbine supplier, over 1000 loose pieces were delivered, received, logged and stored on site. There was a material check in and check out system in place as it was turned over to us for installation. This was extremely beneficial in identifying parts that were missing, defective or wrong. The installation schedule was very demanding and without this system in place, would not have been met.

Another special challenge was staying on schedule while adding 176 piping design changes to the building which added 20.46% additional scope. Ameren elected to run certain parts of the project 6 days/week, 10 hours/day and paid for the premium time to compensate for the added scope. The dedicated team of craftsmen, project managers, and great owner representatives worked hard to successfully complete the project 108 days ahead of schedule.

Project Stats

- Total Project Cost:

- Haberberger Contract Amount: $5,550,000

- Construction Schedule: Winter 2011 – Spring 2012

- Ameren Missouri Project Manager: Scott Wibbenmeyer

- Haberberger Project Manager: Pat Reilly

- Haberberger Field Superintendent: Tim Waldorf

- General Contractor: HR Green Inc.